- Spinning Machinery[10]

- Other Textiles & Leather Products[1]

- Textile Machinery Parts[5]

- Other Textile Machinery[10]

- Textile Dyeing Machinery[2]

- Knitting Machinery[2]

- Printing Machinery Parts[1]

- Sensors[1]

- Inverters & Converters[1]

- Heat Exchanger[1]

- Cooling Tower[1]

- Chemical Product Machinery[2]

- Other Pharmaceutical Machinery[6]

- Other Food Processing Machinery[1]

- Weaving Machinery[1]

- Hand Carts & Trolleys[1]

- Machinery Stock[1]

- Mixing Equipment[6]

- Bag Making Machinery[1]

- Electric Bicycle[1]

- Contact Person : Ms. Zhihong Chen

- Company Name : Wuxi Hongyuan Texmach Export & Import Co., Ltd.

- Tel : 86-510-85816017/85813962

- Fax : 86-510-85800369

- Address : Jiangsu,Wuxi,11 Liangxi Road, Wuxi, Jiangsu Province. China

- Country/Region : China

- Zip : 214062

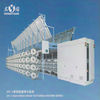

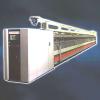

[Super Deal]High Speed Draw Texturing Machine

The FK6.HY-2 High Speed Draw Texturing Machine is suitable for the production of plied and non-torque yarns. This is a split type machine, where A and B side can be operated completely independently. This includes also independent second heater temperatures. The mechanical speed is up to 1200 m/min and the product range from 55-660 dtex for polyester and 22-220 dtex for polyamide. In addition the FK6-HY2S offers advance features for the production of polyamide ply-yarns, non-torque yarns and single S or Z twisted yarns

The Main Technical Feature Side A and B are driven independently, which allows production of different types of yarns on both machine sides. All shafts are driven directly, which eliminates the gear box and drive belts, lowers the noise level and allows high speed production and product quality.

Options The machine can be equipped with Type HY-VII or HY-VIII, individual motor driven or double friction units. Multi-spindle machines are always equipped with double friction units, 4-track heater plates and 2-track cooling plates. This allows production of combined ply yarns, non-torque yarns and other specialty yarns by using all take-up positions, thus doubling the production. Double friction units run with 45 mm diameter disks that are 6 mm thick or 48.6 mm/9mm disks. The units can be stacked up to a 1-9-1 configuration. W2x is a shaft below W2 used for optimizing the interlacing tension. This shaft is an option. For ergonomic considerations there is an optional pneumatic threading device. The on-line yarn tension measuring system is an option for improvement of processing conditions and yarn quality. The optional primary high temperature heater is a HTI design for reduced power, a reduced machine height and an optimum yarn path. This allows convenient operation and maintenance. V-machine with an optimum yarn path can process fine deniers and microfilament yarns.

Main Technical Data

FK6.HY-2 | |||||||

Model:M | Model:V | Model:S | |||||

Specification | Mechanical speed up to(m/min) | 1200 | |||||

Max. friction unit speed(rpm) | 18000 | ||||||

Number of section(section) | 9 or 10 | ||||||

24 | |||||||

Spindles gauge(mm) | 110 | ||||||

Appearance | Total length(mm) | 17360/18800 | |||||

Total height(mm) | 4861 | 5254 | 5154 | ||||

Total width (ex creel)(mm) | 4864 | ||||||

Application range | Product range(dtex) | 55~660 | 22~220 | ||||

Heater and cooling plate | Primary heater length(mm) | 2500 | 2000 | ||||

Secondary heater length(mm) | 1460 | ||||||

Cooling plate length(mm) | 2100 | 1100 | 300+740/760(intensive cooling) | ||||

Power | Main drive(kW) | 88.5 | 80.5 | ||||

Auxiliary drive(kW) | 16 | 18 | |||||

Total power | 9 (kW) | 203.5 | 205.5 | 170.5 | |||

10(kW) | 214.5 | 216.5 | 178.5 | ||||

Take-up package | Max. package dimension(mm) | Ø250X250 | |||||

Weight:inclination/biconical end(kg) | 6/5 | ||||||

Volumn:inclination/biconical ends(dm3) | 11.5/10.1 | ||||||

Feed package | Max. size of feed package(mm) | Ø435 X 250 | |||||

[Super Deal]High Speed Draw Texturing Machine

![[Super Deal]High Speed Draw Texturing Machine](http://img.ecbay.xyz/photo/product419/727156/big-super-deal-high-speed-draw-texturing-machine.jpg)

![[Super Deal]High Speed Draw Texturing Machine](http://img.ecbay.xyz/photo/product335/727155/product-super-deal-high-speed-draw-texturing-machine.jpg)